Mechanical seals are critical components in many industrial applications, including pumps, compressors, and mixers. They are designed to prevent leaks and maintain the integrity of the system. One of the most common questions asked about mechanical seals is whether they require water for proper operation. In this article, we will explore the answer to this question and the importance of proper lubrication for mechanical seals.

Section 1: What are Mechanical Seals?

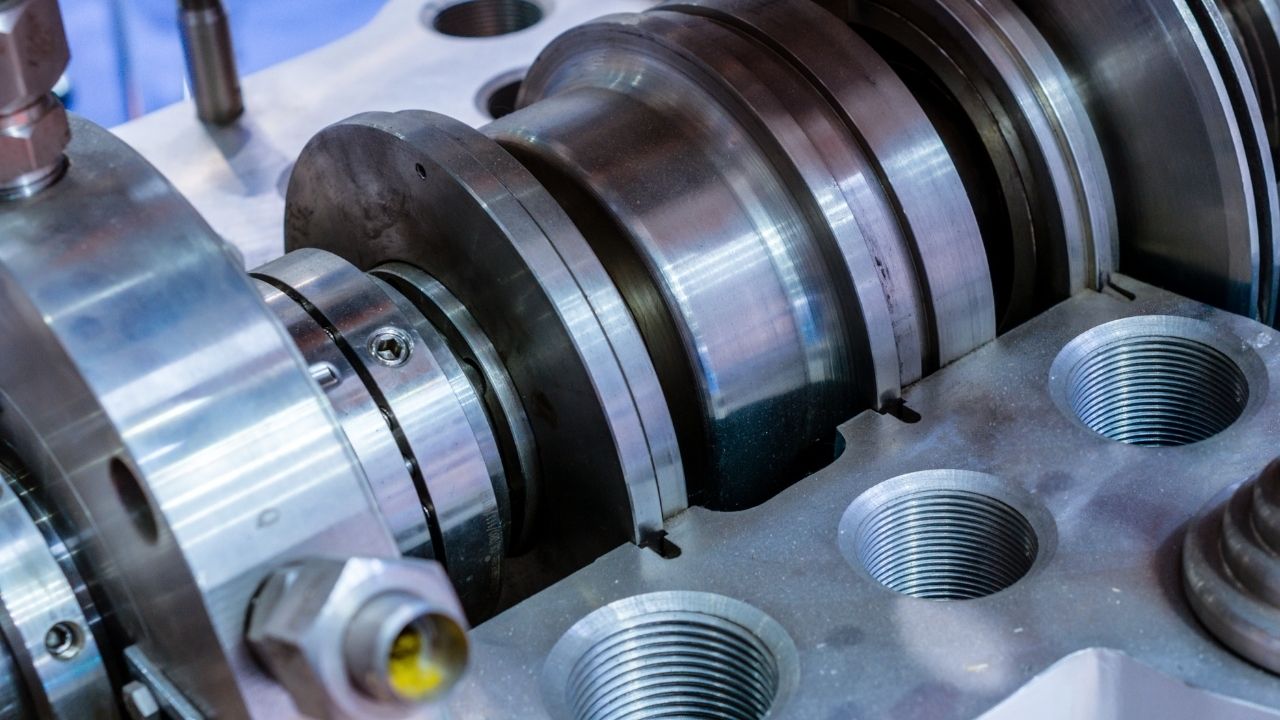

Mechanical seals are devices that are used to prevent fluid leakage in rotating equipment. They consist of two main components: a stationary part and a rotating part. The stationary part is typically mounted on the pump casing or other stationary component, while the rotating part is attached to the shaft of the rotating equipment. The two parts are held together by a spring and a set of sealing faces, which create a barrier to prevent fluid from leaking out of the system.

Section 2: The Importance of Proper Lubrication

Proper lubrication is essential for the proper operation of mechanical seals. Without proper lubrication, the sealing faces can wear out quickly, leading to leaks and other problems. There are several types of lubrication that can be used for mechanical seals, including water, oil, and grease. The type of lubrication used will depend on the specific application and the requirements of the system.

Section 3: Do Mechanical Seals Require Water?

While water can be used as a lubricant for mechanical seals, it is not always necessary. In fact, many mechanical seals are designed to operate without water. However, water can be beneficial in certain applications, such as those that involve high temperatures or abrasive fluids. In these cases, water can help to cool the sealing faces and flush away any debris that may be present.

Section 4: Choosing the Right Lubrication for Your Mechanical Seals

When choosing a lubricant for your mechanical seals, it is important to consider the specific requirements of your system. Factors such as temperature, pressure, and the type of fluid being pumped will all play a role in determining the best lubrication for your application. Consulting with a mechanical seal expert can help you to choose the right lubrication and ensure that your system operates smoothly and efficiently.

Conclusion:

In conclusion, mechanical seals are critical components in many industrial applications, and proper lubrication is essential for their proper operation. While water can be used as a lubricant for mechanical seals, it is not always necessary. Choosing the right lubrication for your specific application is key to ensuring that your system operates smoothly and efficiently. By understanding the importance of proper lubrication, you can help to prevent leaks and other problems and keep your system running smoothly for years to come.